Operation that under specified conditions in a first step establishes a relation between the quantity values with measurement uncertainties provided by measurement standards and corresponding indications with associated measurement uncertainties of the.

Calibration of equipment definition.

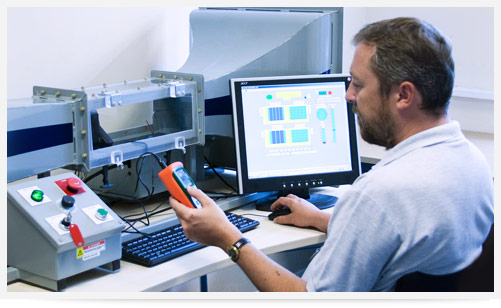

Instrument calibration is one of the primary processes used to maintain instrument accuracy.

The equipment is accordingly adjusted to fine tune its performance to tally with accepted standard or specification.

A calibration certificate includes the result of the comparison and all other relevant information of the calibration such as equipment used environmental conditions signatories date of calibration certificate number uncertainty of the calibration etc.

In other words the known value must have a clearly understood uncertainty to help the instrument owner or user determine if the measurement uncertainty is.

Equipment calibration deals with assessing the accuracy of equipment s results by measuring the variation against a defined standard to decide upon the relevant correction factors.

This definition builds upon the basic definition of calibration by clarifying that the measurement standards used in calibration must be of known uncertainty amount of possible error.

Eliminating or minimizing factors that cause inaccurate measurements is a fundamental aspect of instrumentation design.